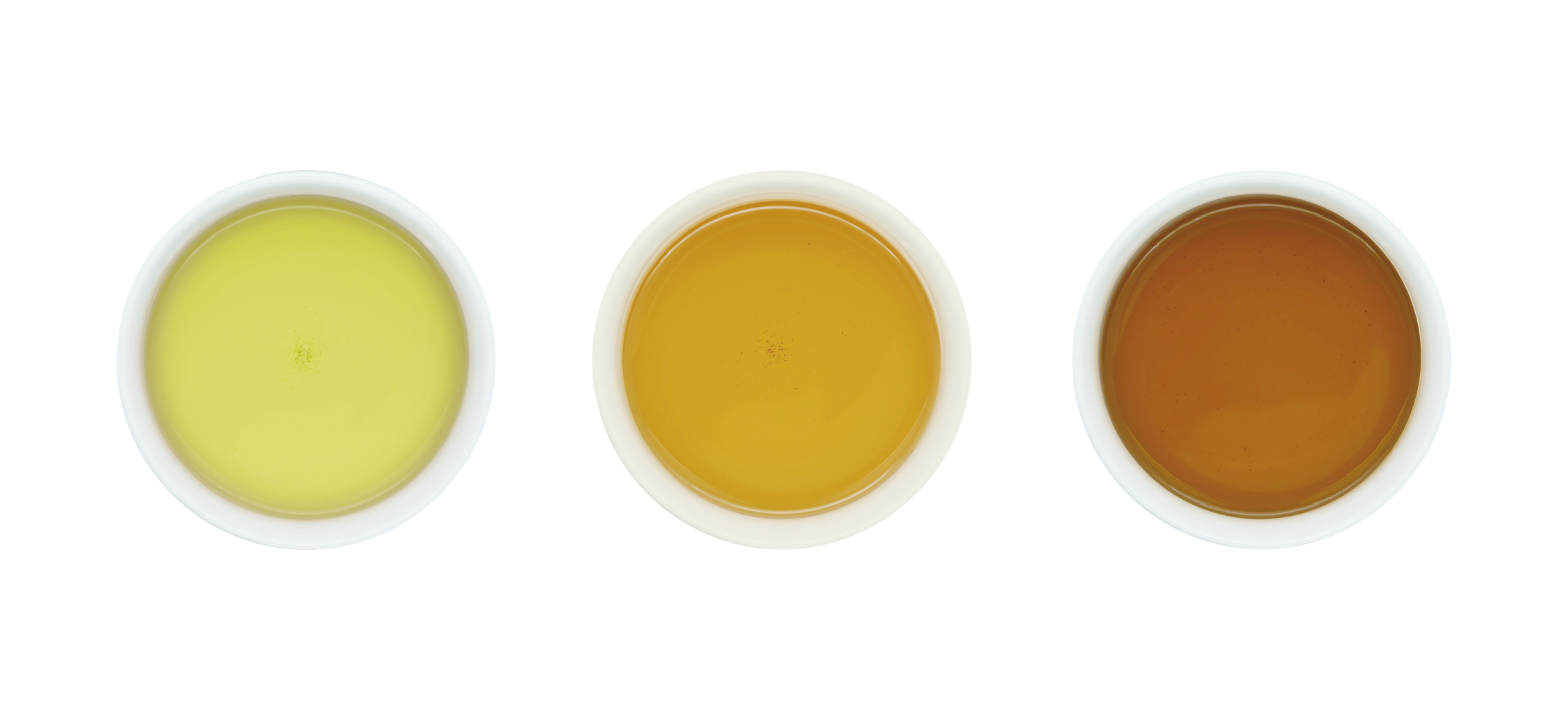

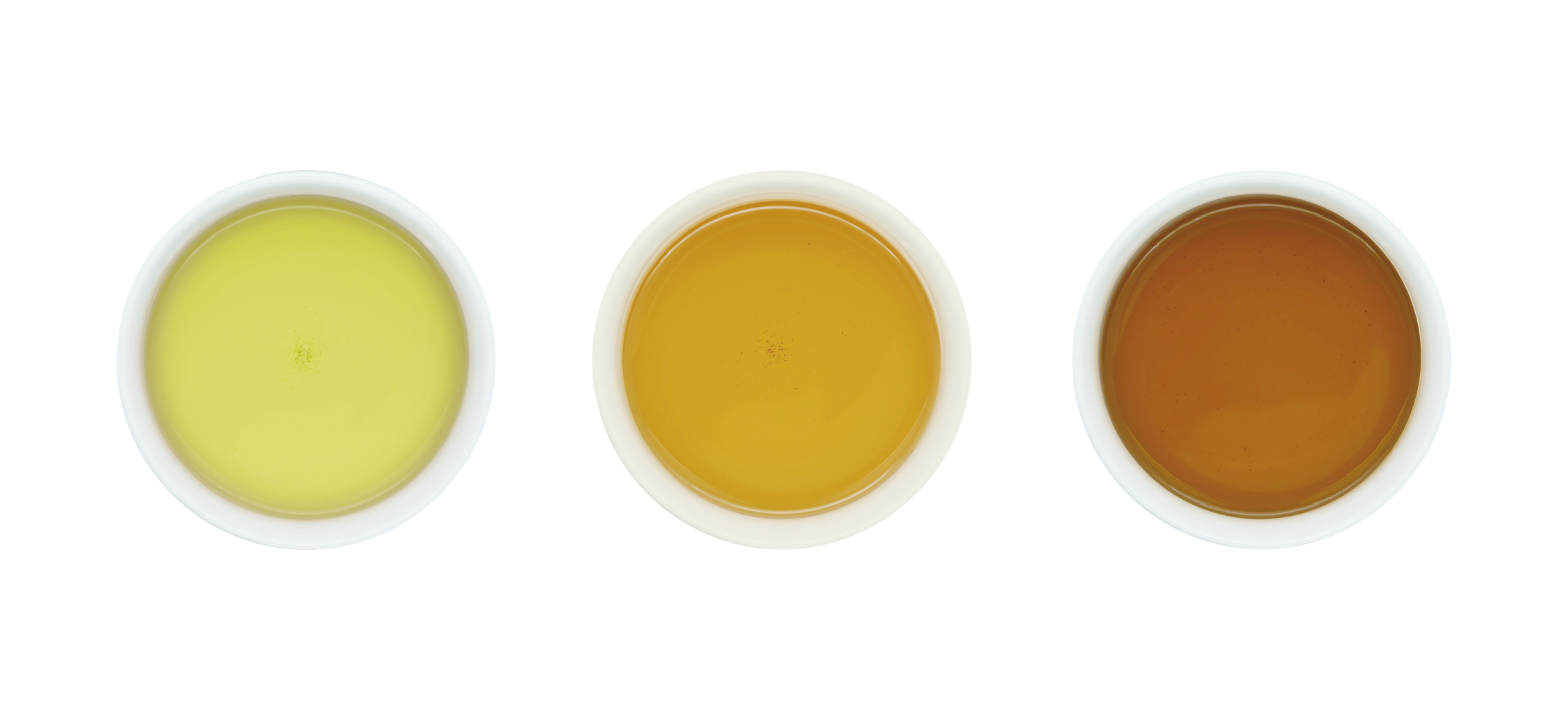

1. Each oolong tea is well oxidized and does not hurt the stomach.

A good oolong tea is not only memorable in taste, but also in the nature of oolong tea.

2. Safe and hygienic packaging environment.

The equipment, lines, and personnel hygiene are all in accordance with the conditions of a hygienic food factory. There is a microbiological testing room to measure the total bacterial count to ensure hygiene.

3. Measuring tools are calibrated regularly.

Floor scales, tea weighing machines, and thermometers are regularly calibrated to ensure adequate weight and stable quality of tea products.

4. Equipment lubrication oil is "food grade".

Conveyor belt track grease and air compressor lubricant are all food grade to ensure food safety

5. Fragile products are regularly inventoried.

Plastic and glass tools are inspected regularly and discarded immediately if cracks are found to ensure food safety.

6. The factory has passed FSSC22000 certification.

FSSC22000 is a certification program developed based on ISO22000 and HACCP, which is one of the strict food safety system certification. It is used to validate the food safety system and to demonstrate that stringent food safety procedures are in place and that hygiene and human health commitments have been met.

7. Tea leaves are tested for pesticide residues on a batch-by-batch basis.

All Yoshantea tea leaves arrive at the Yoshantea factory storage area before being sampled for testing, and the number of samples taken depends on the quantity of tea leaves. All Yoshantea tea leaves have passed the SGS pesticide residue inspection on a batch-by-batch basis to comply with national regulations.

8. "Infrared Foreign Object Sorting Machine" is installed.

Although tea leaves are agricultural products, Yoshantea's tea leaves all go through an "infrared foreign object sorter" to remove foreign objects from the tea leaves, including foreign objects of the same color as the tea leaves, in order to enhance food safety. The capacity of foreign matter selection is 600-1000kg per hour.

9. "Metal Detector" is installed.

Most of Taiwan Oolong tea is in the form of hemisphere, which is easy to cover metal during the production and processing. Yoshantea passes through the "Metal Detector" to remove the metal hidden in the tea leaves in order to enhance food safety. The limit of metal selection ability is Fe 1.2mm (iron), SUS 1.5mm (stainless steel).

10. Analysis of foreign matter in tea leaves.

After Yoshantea tea leaves have passed through the "infrared foreign substance sorting machine" and "metal detection machine", the foreign substances will be analyzed to explore what can be improved in the process of tea making to enhance food safety.

11. Analyze the trend of pesticide use in tea leaves.

After all Yoshantea tea leaves have been tested and analyzed for pesticide residues, the same tea plantation reports will be analyzed for annual trends and provided to the tea farmers as a guide to reduce the amount of pesticides used.

12. Education and training for tea farmers.

Yoshantea will provide "pesticide use trend analysis" and "analysis of foreign substances in tea leaves" to tea farmers and provide them with education and training, so that they can improve the quality of tea leaves in a scientific way.

Safety is the only real good tea.

Yoshantea's Advantage Video