Key Points:

▪ Core Spirit of Food Safety Certification: Consistency in saying, writing, and doing.

▪ Food safety Certification should be for self-examination, not inspection.

▪ Obtaining food safety “certification,” not “accreditation.”

▪ Fewer CCP means good PRP.

▪ Optimizing the food safety system through OPDCA.

▪ The unmeasurable “conscience” is the true food safety.

Hello everyone,

I’m Andy, a tea enthusiast.

Food safety is an important issue. Many food manufacturers use “food safety certification” to prove the safety of their products.

Tea is not only an agricultural product but also a “food.”

Manufacturers claim to pass various food safety certifications.

Does this make the product safer or tastier?

➤ What is Food Safety Certification?

Food factories implement a series of methods and get third-party certification to ensure that all stages, from production to table, meet established food safety standards, thereby maintaining consumer health.

➤ What is the difference between certification and accreditation?

Certification confirms that the system follows regulations,

while accreditation means acquiring a certain capability.

Food safety is a system, not a capability.

➤ What are the food safety certification systems?

The methods to maintain food safety are diverse, and different certification systems contain different contents. There is no “better” certification system

If the food safety system is required by customers, that's another matter. From the simplest to the most complex:

SQF Level 3 is currently the most difficult food safety certification to obtain.

▪ Food Safety Regulations (GHP) > TQF (formerly GMP) > HACCP > ISO 22000 > FSSC 22000 > BRC, SQF

▪ Religious certifications: HALAL certification, Kosher certification

➤What does ISO 22000:2018 mean?

ISO 22000 represents the certification method, and 2018 represents the version. The version is not updated annually.

➤ Using addition to understand food safety systems:

➤ Food Safety Standards/Systems Comparison

Standard/System | Goal | Scope | Focus | Applicable Entities | Standard & Certification | Labeling on Packaging |

GHP | Ensure hygiene during food production, handling, storage, and distribution | Food production and handling processes | Hygiene management, contamination prevention | Food production companies, catering services, etc. | Not a standalone certification standard | No |

TQF (formerly GMP) | Ensure overall food quality, including hygiene, safety, nutrition, taste, appearance, etc. | All stages of food production | Comprehensive quality improvement, emphasizes TQM | All stages of the food supply chain, from producers to consumers | Not a standalone certification standard, helps achieve other quality and safety certifications | Yes |

| HACCP | Ensure food safety during production | Food production processes | Risk-based preventive control | Food production companies | Basis for food safety management systems | No |

| ISO 22000 | Provide unified food safety management standards | All stages of the food supply chain | Standardized food safety management, emphasizes continuous improvement | Various food production and handling companies | International standard for food safety management systems certification | No |

| FSSC 22000 | Ensure the effectiveness of food safety management systems | Based on ISO 22000 standard, combined with ISO/TS 22002-1 and other related standards | Systematic food safety management | Food manufacturing, packaging manufacturing, animal feed manufacturing, etc. | Certified according to FSSC 22000 standard | No |

| BRC | Ensure food safety and quality in the supply chain | All stages of food manufacturing, packaging, storage, and distribution | Supply chain transparency and product traceability | Food manufacturing and retail industries | Certified according to BRC global standard | No |

| SQF | Ensure food safety and quality | Covers the entire food supply chain from farm to table | HACCP-based food safety plan and quality management | Food production companies, suppliers, retailers, etc | Three-tier certification: Level 1 (basic food safety), Level 2 (HACCP), Level 3 (Quality Management System) Level 3: Yes | Level 3: Yes |

HALAL | Ensure compliance with Islamic law | All stages of food production, processing, storage, and distribution | Compliance with Islamic law | All stages of the food supply chain | Certified by Halal certification bodies | Yes |

Kosher | Ensure compliance with Jewish law | All stages of food production, processing, storage, and distribution | Compliance with Jewish law | All stages of the food supply chain | Certified by Kosher certification bodies | Yes |

➤ What is a Prerequisite Program (PRP)?

Emphasizes ensuring the safety of processes “outside” food production.

For instance, pest control and choosing qualified suppliers maintain the safety of food production processes. The 5S management implemented in Japan can be seen as a PRP execution. Food safety hazards often do not come from the production process, such as unwashed hands causing food contamination and food poisoning incidents.

5S: SEIRI (Sort), SEITON (Set in order), SEISO (Shine), SEIKETSU (Standardize), SHITSUKE (Sustain).

➤ What is Hazard Analysis and Critical Control Point (HACCP)?

➤ What is the difference between Critical Control Point (CCP) and Critical Quality Point (CQP)?

| Feature | CCP(Critical Control Point) | CQP(Critical Quality Point) |

| Goal | Control food safety hazards to ensure product safety | Control product quality characteristics to ensure quality consistency |

| Scope | Food safety hazards (biological, chemical, physical hazards) | Quality characteristics (e.g., weight, size, packaging appearance, quantity, sensory quality (color, smell, taste, texture), chemical quality (moisture content, salinity, oil content, sugar content, acidity)) |

| Focus | Food safety management and control measures to prevent safety issues | Quality management and control measures to improve overall product quality |

| Monitoring and Measurement | Monitoring and measuring hazard points | Monitoring and measuring quality characteristics |

| Control Measures | Corrective and preventive measures to ensure product safety | Corrective and preventive measures to maintain and improve product quality |

➤ What is the difference between Critical Control Point (CCP) and Operational Prerequisite Program (OPRP)?

| Feature | Critical Control Point (CCP) | Operational Prerequisite Program (OPRP) |

| Goal | Control specific food safety hazards to ensure hazards are effectively controlled | Control potential food safety hazards to support the effective operation of CCP |

| Scope | Usually targets critical, strictly controlled biological, chemical, and physical hazards | Covers a wide range of operations in the production process, targeting multiple potential hazards |

| Control Measures | Strict, specific control measures must be implemented at specific points | General, daily operational measures to support and maintain a food safety environment |

| Monitoring Frequency | Requires frequent, continuous monitoring and recording | Typically periodic monitoring with lower frequency |

| Critical Limits | Has specific critical limits (e.g., temperature, time, pH value, etc.) | No specific critical limits, but there are operational standards and norms |

| Corrective Measures | Must take immediate corrective action if critical limits are exceeded | Correct deviations to restore standard operations when they occur |

| Applicable Entities | Targets specific processes and steps that may directly affect food safety | Supports CCP operation and maintains food safety in auxiliary processes |

| Recording Requirements | Requires detailed records proving each batch meets safety standards | Requires records but generally simpler, aiming to maintain operational consistency |

| Complexity | Higher, requires professional knowledge and skills to manage | Lower, usually executed by operators according to standard procedures |

| Management Involvement | Requires close supervision and involvement from senior management and technical personnel | Mainly handled by on-site operators and mid-level managers |

Simply put, CCP must immediately stop food safety incidents, while OPRP may not necessarily stop food safety incidents. If unsure, you can use the “decision tree” to determine whether a production step is CCP or OPRP.

➤ Does obtaining SQF Level 3 mean the food tastes better?

No, it only indicates that the food's quality is quite stable.

The food safety management system requires "controllable" and "stable."

If the food tastes exceptionally good, it is another sign of poor quality,

indicating that the quality management limits are out of control.

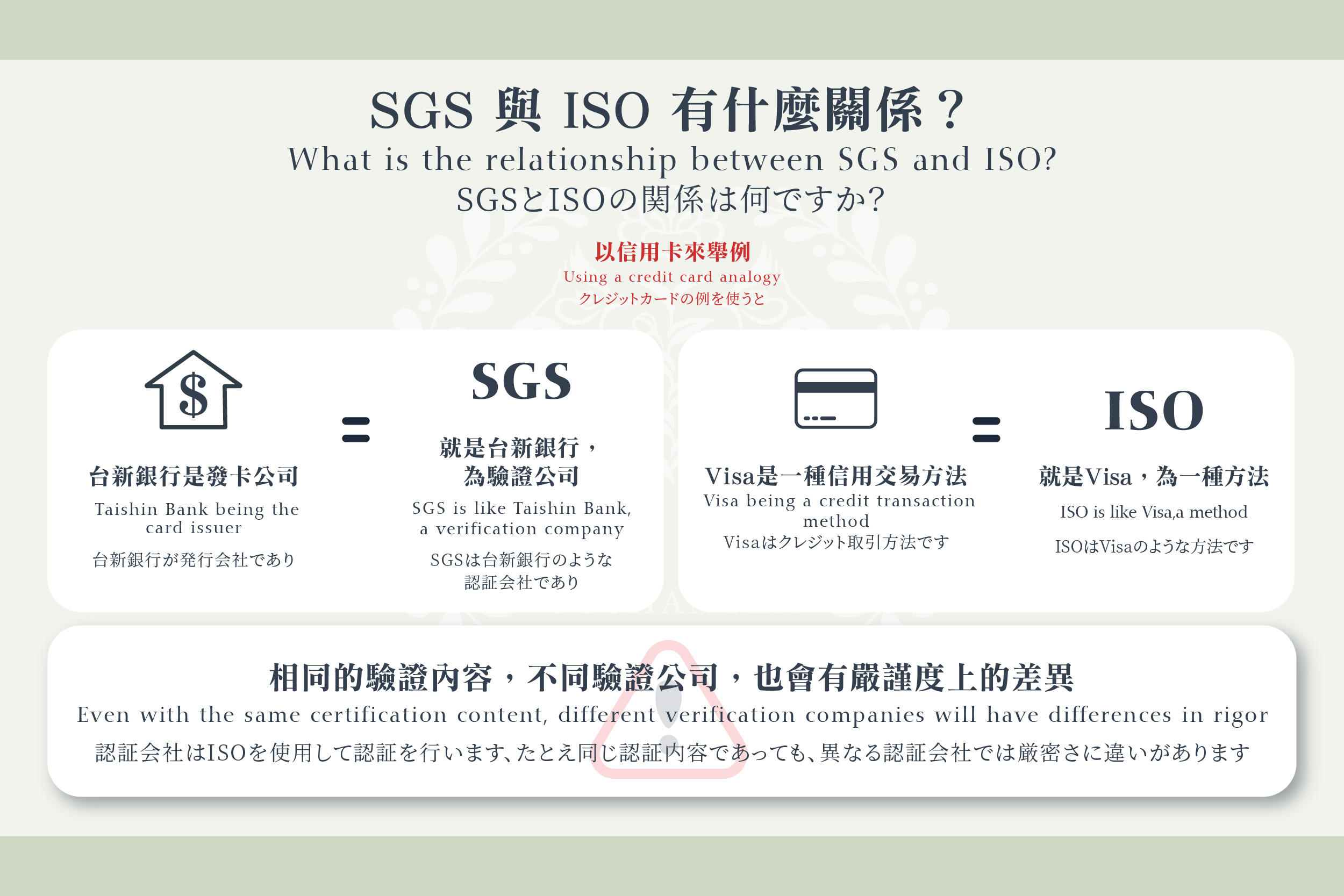

➤ What is the relationship between SGS and ISO?

Using a credit card analogy, Taishin Bank issues Visa cards, with Taishin Bank being the card issuer and Visa being a credit transaction method.

SGS is like Taishin Bank, a verification company, and ISO is like Visa, a method. Verification companies use ISO for certification. Even with the same certification content, different verification companies will have differences in rigor.

➤ Epilogue:

Taiwan introduced HACCP in 2015, and Japan introduced it in 2018.